Mould Room Accessories

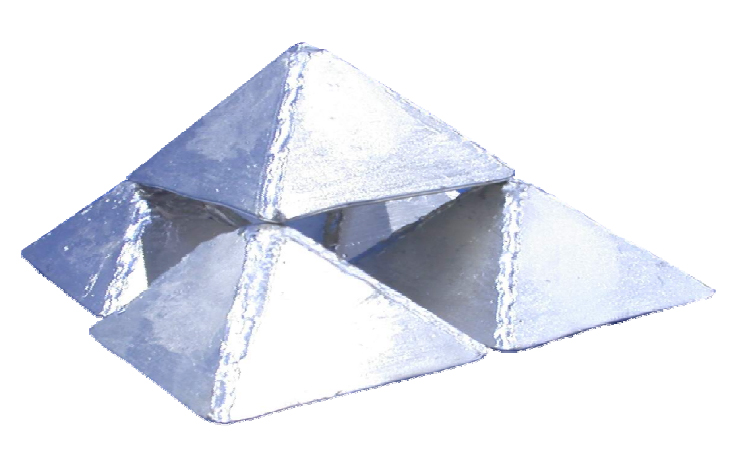

MT49A Alloy Melting

- Fast heat up time

- Very accurate temperature regulation

- Heat-insulated hinged cover

- Security circuits compliant with CE regulations

- Heated outlet valve

- Optional Flexible outlet hose

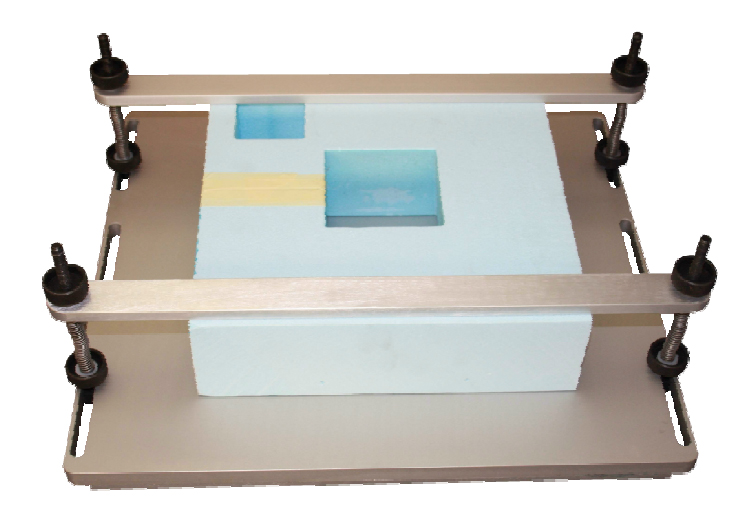

WC2000 Watercooling System

- Cooling plate using water to withdraw the heat from the cerrobend

- Aluminium plate for high heat transfer

- Locking mechanisms to hold Styrofoam in place during casting and cooling process

- Electronic adjustment of temp from 3 to 11 °C

- Takes standard tap water

Workstation with Exhaust

Workstation for melting and casting alloy. Equipped with exhaust system to remove any vapours that might arise during melting of the alloy. The exhaust system is built for performance, yet low noise level (37dB(A) at 3 meters). It offers the ability to control the exhaust volume on control outside the cabinet.

MCP-96 Cadmium Free Alloy

MCP-96 is a low melting point alloy, main ingredient is lead. The melting point is 96°C which can easily be reached in any melting pot. Compared to a MCP-70 (not sold anymore) the contents of this alloy does not include Cadmium, which is highly toxic.

Large Format Digitiser

- Model: DB6-2024 (Surface-Lit).

- Fully compatible with PAR System software

- Size: 737 x 864mm

- Active Area: 508 x 609.6mm

- Resolution up to 12,700 lines per inch

- Accuracy level offered: ±0.010”

Convection Oven

- Space Saving Compact Design

- Non Stick Surface

- Insulated Case

- Dry Heating eliminates inconvenience of using water

- Digital temperature setting in Celsius or Fahrenheit

- 3” touch display for temperature adjustment