VacFix from PAR Scientific

VacFix® Vacuum Cushions are the original, high quality reliable vacuum fixation cushions developed by Par Scientific, they have the thinnest plastic foil available to reduce any build-up effect yet they are extremely ridged and resistant to rupture.

The ability to mould very fine structures and thereby include the highest number of fixation points provides the optimal reproducibility – an increasing issue, both in modern Radiotherapy and also diagnostic procedures.

- The ultimate solution for maximum accuracy

- Very low build-up effect

- Reusable

- Non-toxic

- Perfect fixation

- Fast, clean and easy to use

- Comfortable patient fixation

- Time and money saving

- Two years warranty on weldings

- Customised sizes and shapes

| Cushions | ||

| Product Code | Description | Filling (Litres) |

| 15010075 | Pelvic 150x100cm | 75 |

| 15010080 | Pelvic 150x100cm | 80 |

| 15010085 | Pelvic 150x100cm | 85 |

| 1109040 | Cushion 110x90cm | 40 |

| 10010040 | Thorax 100x100cm | 40 |

| 10010045 | Thorax 100x100cm | 45 |

| 10010050 | Thorax 100x100cm | 50 |

| 10010035 | Cushion 100x100cm round corners | 35 |

| 1005015 | Cushion 100x50cm | 15 |

| 1006015 | Cushion 100x60cm | 25 |

| 1007035 | Cushion 100x70cm | 35 |

| 1007040 | Cushion 100x70cm | 40 |

| 1008020 | Cushion 100x80cm | 20 |

| 100257.5 | Cushion 100x25cm | 7.5 |

| 705012.5 | Cushion 70x50cm | 12.5 |

| 705015 | Cushion 70x50cm | 15 |

| 608015 | Cushion 60x80cm | 15 |

| 606015 | Cushion 60x60cm | 15 |

| 50252 | Cushion 50x25cm | 2 |

| 50252.25 | Cushion 50x25cm | 2.25 |

| 50252.5 | Cushion 50x25cm | 2.5 |

| 1257060 | Special Wing | 60 |

| 1258040 | Elekta SBF Cushion with 2 holes | 40 |

| 9010940 | Special Mammae Cushion | 40 |

| 55295.5 | Cantilever | 5.5 |

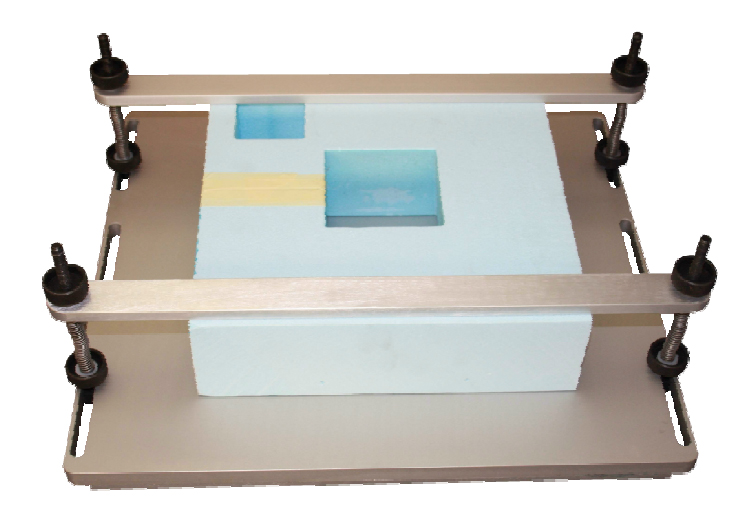

Block Cutter from PAR Scientific

Par Scientific A/S introduced the ACD-4 MK5 following 20 years of experience. This latest unit is now smaller and has a modern DicomRT network interface.

This 5th generation unit has been designed as a small lightweight table version – still having maximum active cutting area. The unit is constructed to be extremely reliable with minimal maintenance equipped with our most modern software version containing any clinical relevant tool to create the most accurate shielding blocks.

The software is very easy to install on a local PC and system set-up is based on the highest level of functionality.

|

Specification |

|

| Cutting Accuracy: | Better than 0.5mm |

| Cutting Speed: | 10 mm per second |

| Active cutting area: | 430 x 420 mm – adjustable |

| Size: | L: 72 cm W: 38 cm H: 72 cm |

| Weight: | 35kg |

| Software: | Full Windows with DICOM RT I/f |

| Accessories: | Label Printer Alloy melting pots Cooling plates Scanners Exhaust System |

Key Characteristics

- Small lightweight table model that can be placed in any location

- 5th Generation electronics offer clinically proven reliability

- Modern software package (Win7/Win10 compatible) with optional Dicom Daemon

- DicomRT is supported

- Very fast cutting speed

- Very fast adjustability of Styrofoam block sizes from 450 x 440 mm and lower with full flexibility on selected size

- “Plug-and-play” functionality for fast and easy installation

- Full accessory package: PAR label Printer, PAR Foam and CadFree Alloy.

- Software contains all relevant user information and guidelines including all relevant 3rd party system drivers

Mould Room Accessories

MT49A Alloy Melting

- Fast heat up time

- Very accurate temperature regulation

- Heat-insulated hinged cover

- Security circuits compliant with CE regulations

- Heated outlet valve

- Optional Flexible outlet hose

WC2000 Watercooling System

- Cooling plate using water to withdraw the heat from the cerrobend

- Aluminium plate for high heat transfer

- Locking mechanisms to hold Styrofoam in place during casting and cooling process

- Electronic adjustment of temp from 3 to 11 °C

- Takes standard tap water

Workstation with Exhaust

Workstation for melting and casting alloy. Equipped with exhaust system to remove any vapours that might arise during melting of the alloy. The exhaust system is built for performance, yet low noise level (37dB(A) at 3 meters). It offers the ability to control the exhaust volume on control outside the cabinet.

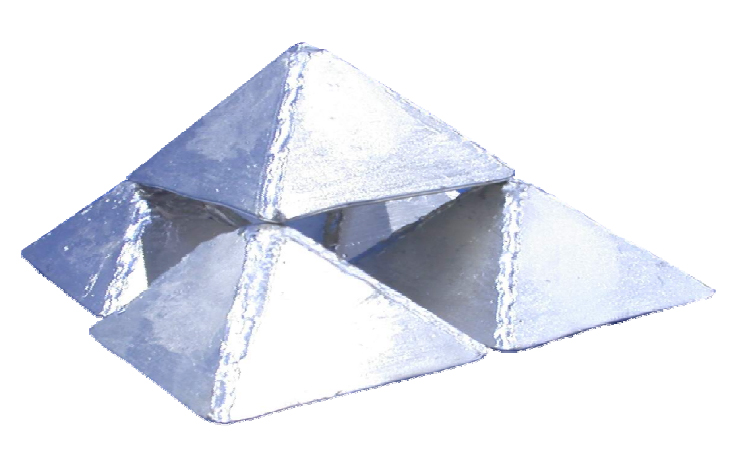

MCP-96 Cadmium Free Alloy

MCP-96 is a low melting point alloy, main ingredient is lead. The melting point is 96°C which can easily be reached in any melting pot. Compared to a MCP-70 (not sold anymore) the contents of this alloy does not include Cadmium, which is highly toxic.

Large Format Digitiser

- Model: DB6-2024 (Surface-Lit).

- Fully compatible with PAR System software

- Size: 737 x 864mm

- Active Area: 508 x 609.6mm

- Resolution up to 12,700 lines per inch

- Accuracy level offered: ±0.010”

Convection Oven

- Space Saving Compact Design

- Non Stick Surface

- Insulated Case

- Dry Heating eliminates inconvenience of using water

- Digital temperature setting in Celsius or Fahrenheit

- 3” touch display for temperature adjustment